New Delhi: India has taken a major step forward in its ambitious Samudrayaan mission, which will send humans 6,000 metres deep into the ocean. Scientists from the Indian Space Research Organisation (ISRO) and the National Institute of Ocean Technology (NIOT) have successfully completed a critical welding process on the titanium crew module of the deep-sea submersible Matsya-6000—the first of its kind in the country.

This precision weld marks India’s first human-rated deep-sea weld on such a thick titanium sphere.

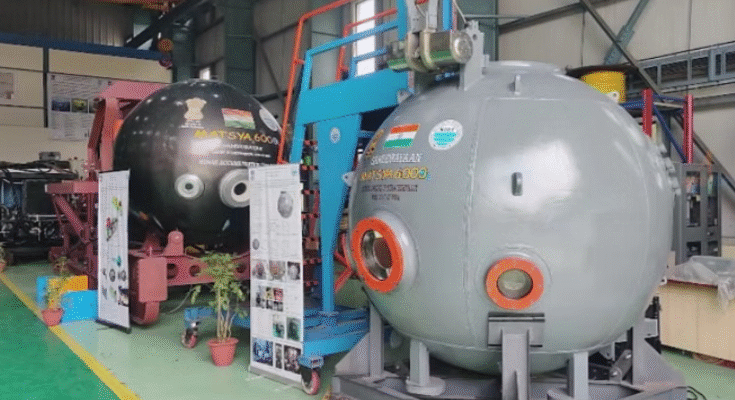

The Matsya-6000 capsule, a spherical submersible with an 80 mm-thick titanium alloy wall and 2,260 mm diameter, is designed to withstand extreme pressure (600 bar) and sub-zero temperatures (as low as -3°C) as it carries three crew members to the ocean floor.

The weld, completed using electron beam welding (EBW)—a technique commonly used in aerospace and nuclear sectors—was carried out after over 700 trials. The process involved high-penetration welding of 80 mm thickness over a 7,100 mm path in just 32 minutes—a first for India.

To ensure safety, ISRO’s Liquid Propulsion Systems Centre (LPSC) in Bengaluru enhanced its EBW capabilities from 15kW to 40kW and upgraded its X-ray radiography facility to 7.5 MeV for non-destructive evaluation (NDE). Advanced NDE methods like Time of Flight Diffraction (TOFD) and Phased Array Ultrasonic Testing (PAUT) were used to verify the weld’s integrity.

This technological breakthrough not only brings India closer to launching its first crewed deep-ocean exploration under the Deep Ocean Mission, but also showcases the country’s growing prowess in space-grade engineering applied to ocean science.