Mahendragiri: In a major stride towards technological self-reliance, the Indian Space Research Organisation (ISRO) has successfully developed an indigenous nozzle divergent for the fourth stage of the Polar Satellite Launch Vehicle (PSLV), replacing the imported Columbium material with Stellite — a cobalt-based alloy enriched with Chromium, Nickel, Tungsten, and Iron.

The breakthrough promises significant cost savings, cutting 90% of the expense associated with the previously imported component.

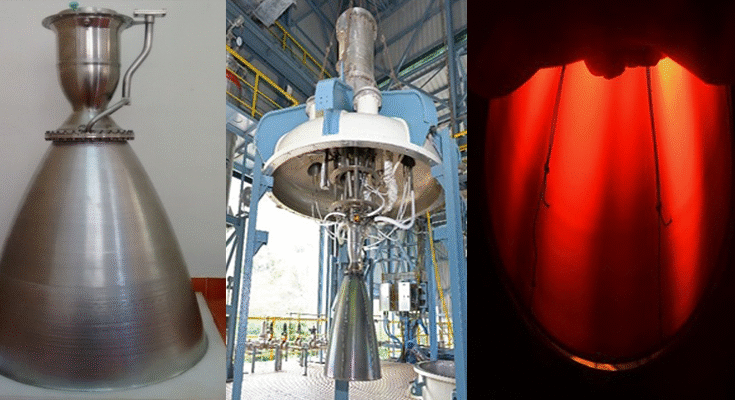

The new nozzle divergent underwent rigorous testing, including a critical hot test on April 8 at the ISRO Propulsion Complex in Mahendragiri, Tamil Nadu. The component demonstrated high thermal resilience, maintaining its strength at temperatures up to 1150°C during a sustained 665-second burn.

This development marks a significant milestone in ISRO’s mission to indigenize key technologies, reduce foreign dependency, and optimize mission costs.

Additionally, the Mahendragiri facility has recently completed successful hot tests of the human-rated Vikas Engine, which is set to power the Gaganyaan human spaceflight mission.

Designed and developed domestically, the Vikas engine—named in honor of Vikram Sarabhai, the father of India’s space program—will be used in a clustered configuration on the LVM3-G launch vehicle to ferry astronauts into space.